COMPLIANT ELECTRICAL SAFETY SOLUTIONS

Unlimited PPE Inc. is now SureWerx Technical Services!

Read the press release.

WE CONNECT YOU WITH THE BEST AVAILABLE ARC FLASH & SHOCK SOLUTIONS SO YOUR WORKERS CAN BE SAFE AND COMPLIANT.

SureWerx Technical Services represents industry leading electrical safety product and service providers. We’re helping to save lives by promoting compliance with Workplace Electrical Safety Standards including NFPA 70E & CSA Z462.

Since 2008, we’ve demonstrated our ability to successfully combine products and services from multiple vendors to form an unparalleled combination of fit for purpose and turnkey electrical safety solutions ranging from Arc Flash PPE to an Electrical Safety Program implemented as part of an overall occupational health and safety management system.

FULL SCOPE SOLUTIONS

ELECTRICAL SAFETY PROGRAMS

Employers must have an Electrical Safety Program for compliance with the NFPA 70E or CSA Z462 Standards. We were the first ever to offer an off-the-shelf product solution that you can license and own. Our complete documentation package is fully updated to the latest Standards and includes everything you’ll ever need to finally develop a world class program at your company.

TEMPLATE DOCUMENTATION

Take control of electrical safety compliance at your facility with our comprehensive package of template files. The core Electrical Safety Program is provided with instructional files, engineering specifications, training materials, audit documentation, forms, tables, flowcharts and more. This can be a do-it-yourself project or fully facilitated by one of our Expert Consultants. We offer a variety of programs that best suit your needs:

- Small Contractor

- Single Site Industrial, Commercial or Institutional

- Enterprise Wide Organization

Arc Flash & Shock Training

We offer training solutions for your entire workforce. Electrical Safety Training is more than just arc flash videos, pictures of burn injuries and storytelling. All workers require appropriate electrical safety training.

SureWerx Technical Services offers innovative solutions using eLearning, Instructor-led training, or Blended Learning formats.

eLearning

We offer fully compliant eLearning courses based on either the NFPA 70E or CSA Z462 Standards. Courses are available for both Electrical Workers and Non-Electrical Workers. Select the course that’s appropriate for the workers risk level.

eLearning courses are available online, or as licensed SCORM files for hosting at your company.

eLearning is available online 24/7 or licensed for use on your company’s learning management system (LMS). Workers have access to their training from anywhere using an internet connection. Alternative solutions using USB flash drives are also available.

An enhanced learning environment with employees learning from one another as well as from the Instructor. Classrooms can be customized as learning labs with electrical equipment allowing workers to practice performing work tasks within a workflow process.

Uses industry accepted best practice Standards in support of meeting OSHA and OH&S Regulatory due diligence for arc flash and shock. Developed by industry leading Subject Matter Experts our eLearning is an effective form of training for your workers.

Instructor-Led Training

A variety of traditional Instructor-led classroom options to fit any need. Our classroom training courses are delivered at your site by Electrical Safety Subject Matter Experts with years of consulting experience. Your workers benefit from instruction that includes comprehensive student materials, hands-on arc flash & shock PPE demonstration, learning aids and practical work task exercises.

All of our training is designed to complement your Electrical Safety Program by using workflow process flowcharts, risk assessment tables and field level documentation examples.

This most common form of training still has a place in today’s learning management industry. As demographics shift to younger workers Instructor-led courses are best used for site specific training on policies, work methods and specialized equipment.

An enhanced learning environment with employees learning from one another as well as from the Instructor. Classrooms can be customized as learning labs with electrical equipment allowing workers to practice performing work tasks within a workflow process.

Course content can be customized to include site specific curriculum from the Employers Electrical Safety Program. ESPS offers consulting support to review existing documentation and policies to ensure full alignment with the Employers safety management system.

Blended Learning

Innovative solution that combines Instructor-led classroom training with eLearning. The most efficient way of ensuring Qualified Electrical Workers receive adequate training.

Workers must first complete their eLearning course for training on either the NFPA 70E or CSA Z462 Standard, including how to complete an arc flash risk assessment. An Expert Instructor then provides a full day Application course focused on the practical application using work task exercises.

Most beneficial type of training for Qualified Electrical Workers using eLearning as a prerequisite to traditional Instructor-led training courses. Blended learning is best training option for Employers who provide their own internal electrical safety training.

Students have the ability to take the eLearning prerequisite portion of their blended learning anytime prior to classroom training. Our eLearning is available online 24/7 or hosted on the Employers LMS for unlimited internal use.

Students learn through a variety of activities that apply to many different learning styles. Everyone benefits from workers spending less time demobilized in a classroom. Students are able to prepare and obtain prerequisite knowledge at their own pace.

VOLTAGE CHECKING BAND

Smart wearable alerting device that protects workers by sensing when they get too close to energized conductors or circuit parts. The first, and only personal safety device worn directly on a worker’s wrist that can help prevent an electrical contact incident. It notifies the worker of danger and helps reinforce the limits of approach.

Learn More About The Voltage Band

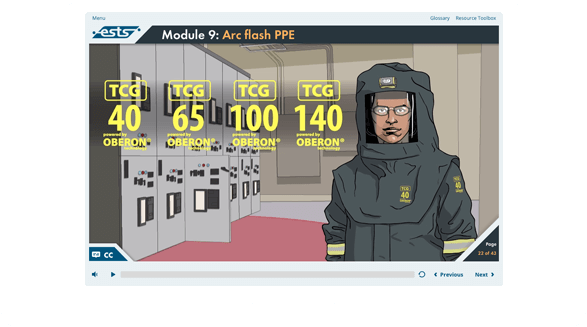

Arc Flash PPE

Arc Flash personal protective equipment (PPE) consists of specially designed and appropriately tested products suitable for use by workers that need protection from the thermal effects of an arc flash hazard.

Employer Requirements

Employers are required to complete an arc flash risk assessment to identify arc flash hazards; estimate both the likelihood of occurrence and potential severity; and determine if additional protective measures are needed, including the use of arc flash PPE.

When additional protective measures include the use of arc flash PPE, the employer must also determine appropriate safety-related work practices; the arc flash boundary; and the PPE that qualified workers must use.

Employers are required to complete an arc flash risk assessment to ensure workers within the arc flash boundary wear appropriate full body protection when it is determined that arc flash PPE is necessary based on an arc flash risk assessment. Refer to all applicable Acts, Codes and Regulations including Standards like CSA Z462 and NFPA 70E for full arc flash PPE requirements.

SureWerx Technical Services can assist you by helping to explain these steps and provide recommendations that include training, incident energy/arc flash calculations, arc flash PPE selection and overall Electrical Safety Programs that combine everything together into one full scope, compliant solution.

How to Select Arc Flash PPE

Appropriate arc flash PPE is selected based on the potential thermal incident energy exposure, as determined by an employer’s arc flash risk assessment. For a work task on a specific type of equipment this can be done using the incident energy value in calories per square centimeter (cal/cm2) or an Arc Flash PPE Minimum Arc Rating, but not both.

Arc-ratings for all arc flash PPE are provided in cal/cm2 as performance ratings for selection purposes. The arc flash PPE arc-rating must match or exceed the thermal incident energy value required by the employer’s arc flash risk assessment. It is noted that despite the employer’s best efforts their arc flash PPE may not provide adequate protection from arc flash hazards.

SureWerx Technical Services offers training solutions including eLearning that can help teach you how to properly select arc flash PPE.

What is An Arc-Rating

Arc Flash PPE is specially designed and appropriately tested to determine its ability to protect a worker from receiving a 2nd degree skin burn injury if exposed to an arc flash incident. The protection provided by arc flash PPE is called an arc rating. This testing is done on the fabric or a finished product using various different testing methods according to applicable Standards. In North America, ASTM Standards are used at ISO accredited laboratories including Kinectrics in Toronto, Ontario, Canada.

There are various different types of arc ratings, the most appropriate are an ATPV or EBT rating. Both of these values are provided in calories per square centimeter (cal/cm2). In product testing, the lowest of the two arc ratings is used as the protective ability of the arc-tested product.

ATPV, Arc Thermal Performance Value, the incident energy level at which there is a 50% probability of sufficient heat transfer to cause the onset of a second-degree skin burn injury.

EBT, Breakopen Threshold Energy, the incident energy level at which there is a 50% probability of the formation of holes or tears in the layer closest to the skin.

Compliance

The 2024 edition of NFPA 70E & CSA Z462 Standards include requirements for arc flash PPE suppliers or manufacturers to demonstrate their level of conformance to all applicable Standards. This important change applies directly to the compliance of available arc flash & shock PPE.

It is now required for the supplier or manufacturer to provide a declaration of conformity for any PPE, tools or equipment. The benefit for the employer is to have the ability to hold the supplier or manufacturer accountable for their product performance. For arc flash PPE, the only way to know if a product will protect your worker is to expose it to an arc flash. With the new conformity assessment requirements, employers can evaluate the compliance of a product based on the following three levels as defined by ANSI/ISEA 125:

Level 1

Self-declaration with a Supplier’s Declaration of Conformity.

Level 2

Self-declaration under a registered quality management system and product testing by an accredited laboratory and a Supplier’s Declaration of Conformity.

Level 3

Certification by an accredited independent third-party certification organization.

Oberon is a World leader and Pioneer for Arc Flash PPE solutions. Visit their website for guidance on product selection and overall compliance. They’ve spent more time testing their products than any other manufacturer. The Oberon brand is the safest available Arc Flash PPE on the market.

Learn More About Oberon